ZLPG Series Chinese Medicine Extractum Spray Dryer

ZLPG Series Chinese Medicine Extractum Spray Dryer

NTRODUCTION

NTRODUCTION

Chinese medicine extractum high-speed centrifugal spray device is an application of centrifugal spray drying technology in particular material. It is also a drying equipment that uses high-speed centrifugal atomization to make materials dispersed into a mist, and have full access to hot air to achieve instant drying and produce powder products. It is designed to solve medicine extractum and plant liquid.

WORKING PRINCIPLE

This machine is fully enclosed and all parts are made of stainless steel, with three-level purification devices, which make filtered air reach the class 100,000 requirement. There is cold-wall devices equipped on the cylinder and its top to keep the wall temperature under 80℃. The drying tower is equipped with air-brush weeping device; coking and deterioration phenomenon won’t occur to Chinese medicine extractum powder dried by this machine. It greatly increases the yield rate of powder (95%), without the phenomena of medicine mixing and sticky wall.Chinese medicine extractum high-speed centrifugal spray device is application of centrifugal spray drying technology in particular material. It is also drying equipment that uses high-speed centrifugal atomization to make materials dispersed into a mist, and have full access to hot air to achieve instant drying and produce powder products.

FEATURES

◎ The tower is equipped with cold-wind jackets.

◎ The tower is equipped with automatic vibration devices.

◎ The tower and piping are equipped with quick opening cleaning hole and drain hole.

◎ It can be equipped with automatic-control thermostat feed pot.

◎ It can be equipped with manual high-pressure washing-tower standard accessories.

◎ Portion in contact with material were made of stainless steel; (or all stainless steel);

◎ Material collection use two-level cyclone dedusting device or one-level cyclone and wet deduster.

◎ Inlet air temperature can realize automatic control and continuous apparatus.

◎ It can be equipped with gas cleaning device.

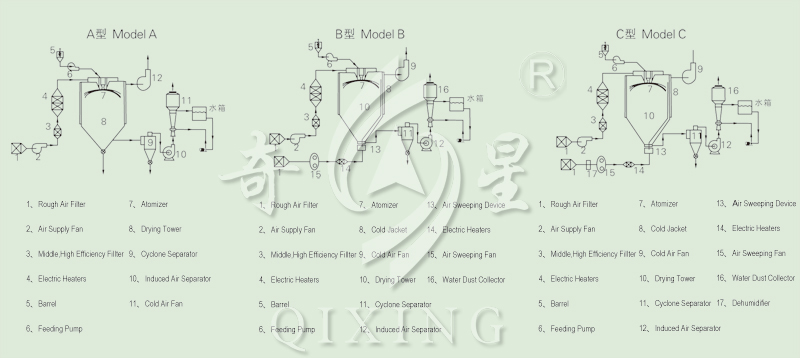

STRUCTURE SCHEMATIC

TECHNICAL PARAMETERS

|

Model/Item |

ZLPG-15 |

ZLPG-20 |

ZLPG-25 |

ZLPG-32 |

ZLPG-38 |

ZLPG-40 |

ZLPG-47 |

ZLPG-52 |

ZLPG-58 |

|

|

Max. Evaporation Capacity |

5 |

10 |

25 |

50 |

80 |

100 |

150 |

200 |

300 |

|

|

Processing Capacity(kg/h) |

6-7 |

12-14 |

25-34 |

50-68 |

80-108 |

100-135 |

150-203 |

200-270 |

300-406 |

|

|

Output Capacity (kg/h) |

1-2 |

2-4 |

4.8-7.2 |

9.2-14 |

14.8-22.4 |

18.4-28 |

28-42 |

36.8-56.4 |

55-85 |

|

|

Solid Content of Damp Material (%) |

18-25 |

|||||||||

|

Moisture Content of Finished Product (%) |

3-5 |

|||||||||

|

Power(kw) |

36 |

45 |

63 |

99 |

132 |

153 |

204 |

246 |

330 |

|

|

Heat Source |

Steam + electricity |

|||||||||

|

Product Collecting Method and Efficiency |

Two-grade cyclone duster or one-grade cyclone duster : The product collecting efficiency for one-grade duster is ≥95% |

|||||||||

|

Automatic Control Instrument |

Indicator of temperature of hot air and humidity of air exhaust |

|||||||||

|

Inlet Air |

150-200 |

|||||||||

|

Outlet Air |

80-100 |

|||||||||

|

Overall Dimension (mm) |

L |

5000 |

5500 |

7000 |

8000 |

9800 |

11000 |

12200 |

14100 |

15000 |

|

W |

3000 |

3500 |

4000 |

5000 |

5700 |

6200 |

7000 |

7800 |

9000 |

|

|

H |

4500 |

4600 |

5200 |

6500 |

7600 |

8100 |

9000 |

9850 |

11100 |

|

Note: 1.The actual dimensions can be determined according to the actual situation of the customer, the above size is for reference only.

2.The above evaporation is the maximum evaporation. Xinggan Drying Equipment

Xinggan Drying Equipment