LZG Series Helical Vibration Dryer

LZG Series Helical Vibration Dryer

INTRODUCTION

Wet materials enter into the helix bed from the inlet on the top, under the effect of exciting force in circumferential direction and the gravity, along the helix bed, having a jump motion from top to the bottom. Meanwhile, the clean hot air enters into the helix bed from the bottom, after full heat transfer and mass transfer with materials distributed the in the bed, then exhausts from the outlet at the top. So the materials achieve the purpose of being dried.

APPLICAITON

The drying equipment is mainly used in drying of traditional Chinese medicine pills; it is also applied to drying of granular, short-strip and ball materials in industries of chemical pharmaceutical,food,plastics, building materials, forage,and so on.

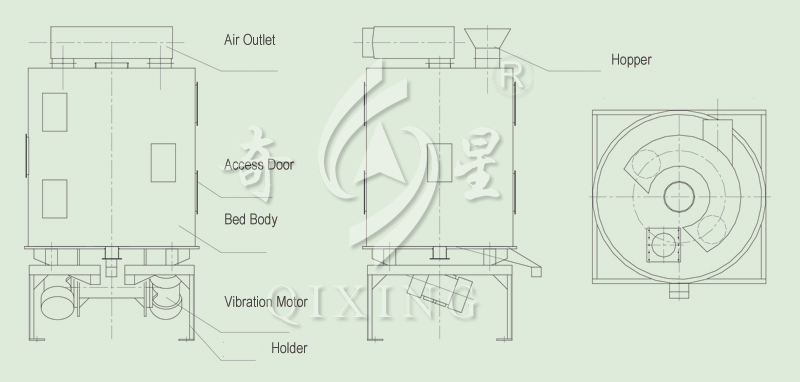

STRUCTURE SCHEMATIC

FEATURES

◎ Hot air goes through the material layer and has reverse flow with material repeatedly, thus the heat exchange is sufficient, ensuring high thermal efficiency.

◎ Compact structure and small covering area.

◎ Residence time in the bed can be adjusted; it is easy to operate.

◎ Materials have a circulation motion from bottom to the top along helix bed, meanwhile they have jump motion themselves, thus increasing the contact between material and hot air, and enhancing the drying effect.

◎ Continuous inlet and outlet of materials are suitable for pipeline operation. It is easy to meet "GMP" standard and can replace the traditional box-type drying.

◎ It basically does no damage to surface and shape of materials; it not only maintains the roundness of pill but also greatly reduces the broken rate.

TECHNICAL PARAMETERS

| Model/Item | LZG-1.0 | LZG-1.2 | LZG-1.4 | LZG-1.6 | LZG-1.8 |

| Diameter (mm) | 1000 | 1200 | 1400 | 1600 | 1800 |

| Power (kw) | 2×1.1 | 2×1.1 | 2×1.5 | 2×1.5 | 2×2.2 |

| Overall size (m) | 1.2×1.2×2.7 | 1.4×1.4×2.7 | 1.6×1.6×3.3 | 1.8×1.8×3.3 | 2.0×2.0×3.3 |

| Weight (kg) | 1400 | 1680 | 2800 | 3100 | 3800 |

| Inlet air temperature (℃) | 60-200 | 60-200 | 60-200 | 60-200 | 60-200 |

| Amount of air(m3/h) | 1487 | 2380 | 3721 | 4462 | 5930 |

Xinggan Drying Equipment

Xinggan Drying Equipment